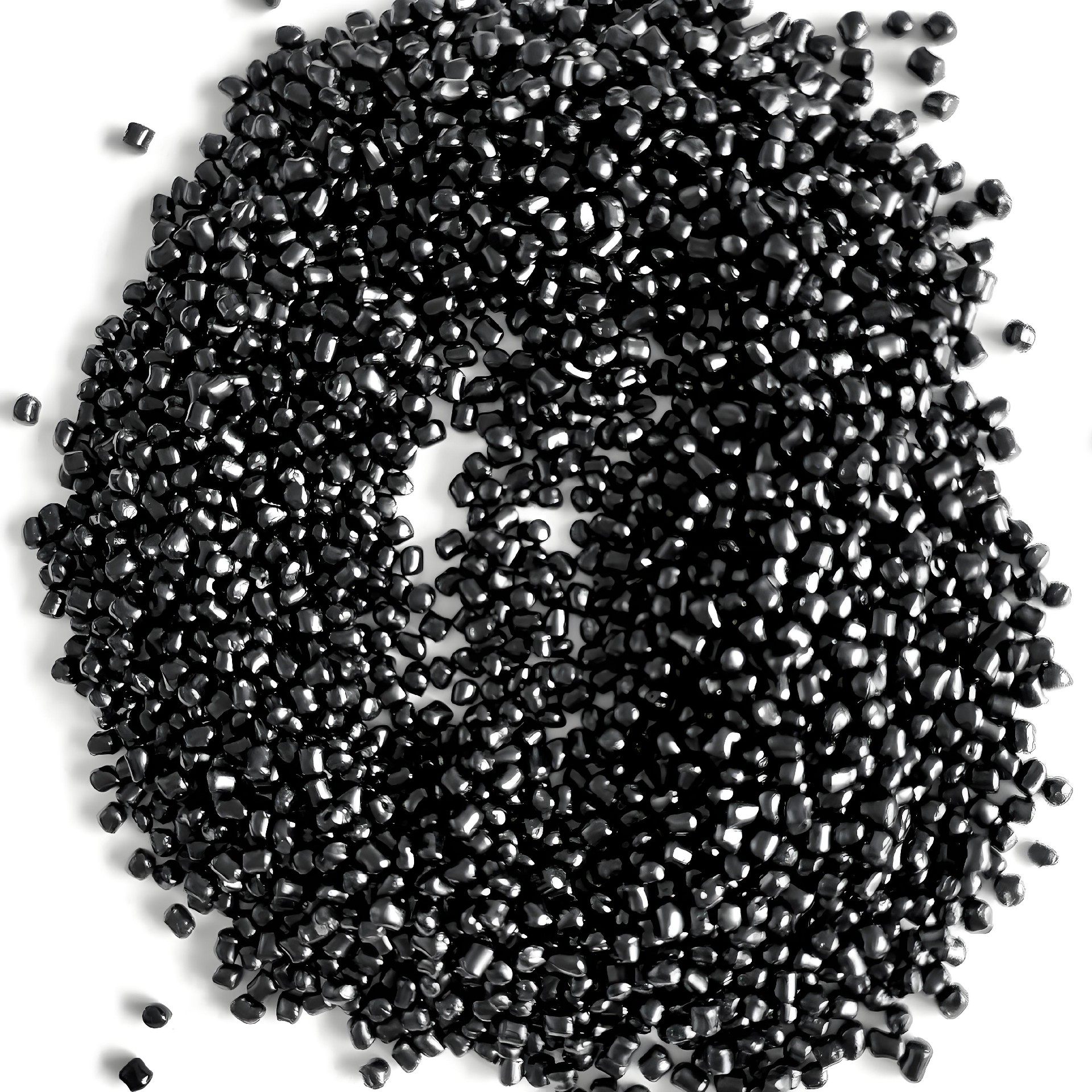

Exploring the Maximum Carbon Black Content in Black Masterbatches: A Technical Perspective

As a masterbatch manufacturer specializing in color concentrates,

understanding the optimal carbon black loading in black masterbatch formulations is crucial for product performance and client satisfaction.

This article examines the technical boundaries of carbon black concentration while maintaining practical processability.

Carbon Black Fundamentals

Carbon black serves as the primary pigment in black masterbatches, providing:

- UV protection

- Electrical conductivity

- Deep jetness

- Cost efficiency

Typical loadings range from 20-40% in standard formulations. However, maximum achievable concentrations depend on multiple factors:

Key Determinants of Maximum Loading

1. Carrier Resin Compatibility

- LDPE: 45-50% max

- PP: 40-45% max

- PA: 35-40% max

2. Dispersion Technology

High-shear twin-screw extruders enable 5-10% higher loadings than single-screw systems

3. Carbon Black Type

Furnace blacks (N550/N330) permit higher loadings than channel blacks

4. End-Use Requirements

- Film applications: ≤35%

- Injection molding: ≤50%

- Conductive grades: 30-40%

Technical Limitations

While lab tests show theoretical maximums up to 60%, practical production constraints limit commercial formulations to:

- Standard grades: 45% max

- Specialty grades: 50% max

Beyond 50%, manufacturers face:

- Reduced melt flow index (MFI <5 g/10min)

- Compromised mechanical properties

- Screw slippage during extrusion

- Increased die pressure

Industry Benchmarks

Recent market analysis reveals:

- 78% of commercial products contain 25-40% carbon black

- Only 12% exceed 40% loading

- 0.7% reach 50% threshold

Optimization Strategies

To safely maximize carbon black content:

1. Use surface-treated grades (e.g., oxidized CB)

2. Implement multi-stage compounding

3. Add 2-5% dispersing agents

4. Maintain melt temperature ≤240°C

Future Trends

Emerging technologies may push boundaries further:

- Nano-structured carbon blacks (+8% loading potential)

- Reactive extrusion methods

- Hybrid pigment systems

Conclusion

While 50% carbon black represents the current practical maximum in production environments,

continuous process innovations are gradually expanding formulation possibilities.

Masterbatch manufacturers must balance pigment concentration with processing parameters

and end-use performance requirements to deliver optimal solutions.

微信扫码 关注我们

微信扫码 关注我们

24小时咨询热线13561588568

移动电话18769608281