Color:White/Gray/Black

Color:White/Gray/Black

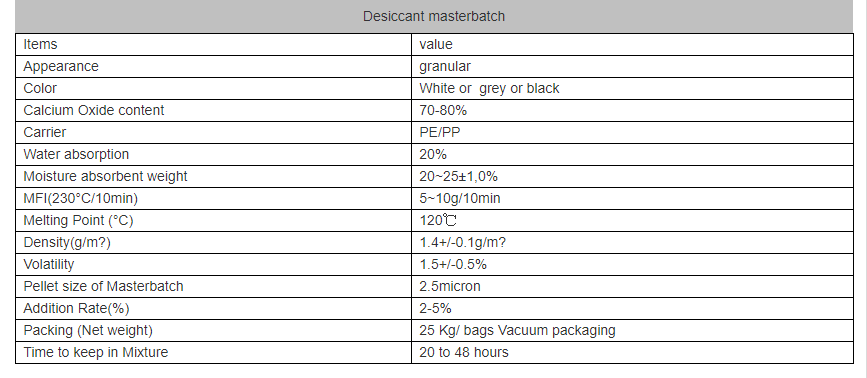

Carrier:PE/PP

MFI( g/10min):0.5-50

Density(g/cm3):1.5-2.1

Volatility:1.5±0.5%

Time to keep in mixture:24 hours

Light fastness:≥5

Filler:Calcium Oxide

Water absorption:≤20

CaO content:75%-88%

Defoaming Drying Agent Details

Desiccant masterbatch can be widely used in PP/PE recycled plastic production. Calcium oxide is the main raw material. When the desiccant masterbatch being applied, the moisture in the material can be absorbed. The calcium oxide is reduced to calcium hydroxide, and then the fine particles of calcium hydroxide are evenly dispersed in the plastic products after blended with the resin

Defoaming Drying Agent Advantage

Better water absorption

Perfect diffusing

Less effect on products glossing and coloring

Good corrosion resistance

Powerful water absorbing up to its weight 20%

Non-toxic and environment-friendly

No hurt on worker

Defoaming Drying Agent Applications

Wire drawing: Fiber, Carpet, Textiles, Upholstery, etc

Injection Molding: Automotive, House wares, Electronic, Construction, Furniture, Toys, etc.

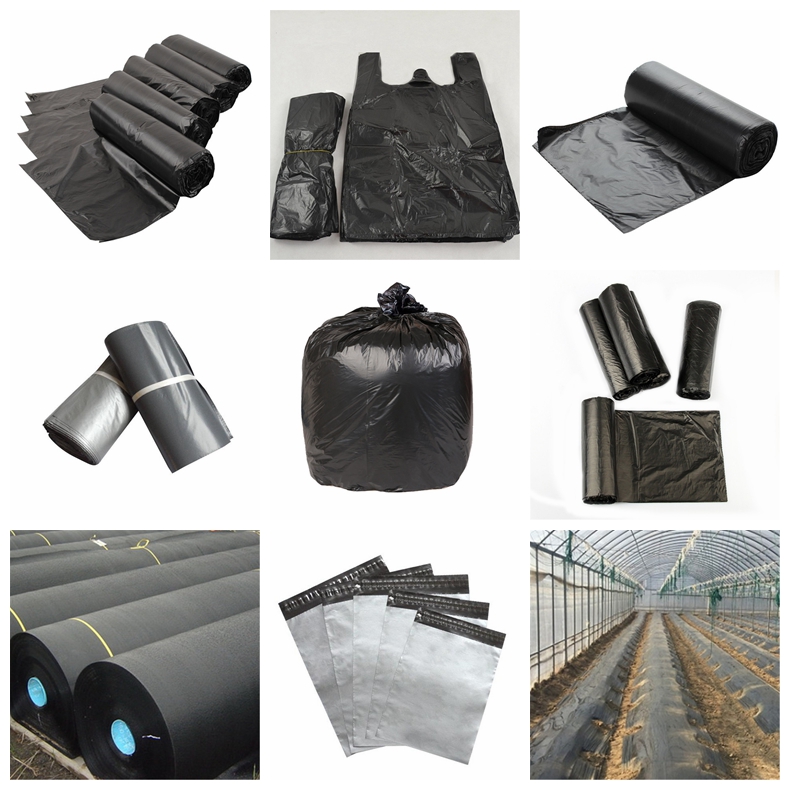

Film: Shopping bags, casting film, multilayer film, etc.

Blow Molding: Medical & Cosmetic container, Lubricant & Paint container, Mineral water bottle, carbonated soft drinks bottle, oil bottle, etc.

Packaging & Shipping

Why choose us?

We like to develop a long term business relationship with you.

Our packing bags can be used again and again 10 times to basically be scrapped, and our can be used repeatedly 20 times.

Our masterbatch uses environmental protection technology, save the environmental protection expense.

Our masterbatch is safer to use, and ensure worker safety.

We can provide a complete set of data analysis.

We can provide a large number of mechanical operation images to ensure the quality of production.

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable.

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

Testing equipments

FAQ

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Is there other way to get the desired color?

We send our sample to customer for test. We produce according to orders after the sample got approved by the customers.

Do we provide free sample of the products?

Of course, please feel free to tell me your specific requirements, and then we will make the corresponding customized sample to you.

微信扫码 关注我们

微信扫码 关注我们

24小时咨询热线13561588568

移动电话18769608281